Manufacturers have been benefitting from the use of vertical carousels for decades to reduce waste and increase their productivity. Whether your need is for textiles and fabrics, small parts storage, or custom applications, we have the ability to integrate a quality vertical storage concept into your business.

Sheet Metal Vertical Lift

The Vertical Lift is an automated sheet metal storage system designed to safely take advantage of high ceilings while implementing a goods-to-operator workflow. Basic ease of access and faster retrieval times can improve capital equipment output by up to 15-20%. The Sheet Metal Vertical Lift System is a value-added solution for warehouse automation programs, and improves both productivity and safety.

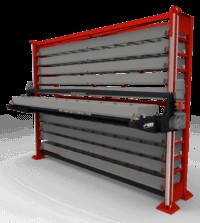

Bar Stock / Linear Vertical Lift

The Vertical Lift for bar stock and linear materials is adaptable and can accommodate a multitude of sizes and applications. The cartridges are designed to accept linear objects such as bar stock, pipes, and beams. They can also be custom fit with molds for custom applications such as press brake dies which keeps your material storage safe, organized, and effective. The Bar Stock Vertical Lift System is a value-added solution for warehouse automation programs, and improves both productivity and safety.

Wire & Cable Solutions

The Wire Carousel is a motorized wire storage system designed to store, retrieve, and dispense various ranges of wire, cable, rope, chain, hose, and other materials stored in reels or spools vertically which effectively utilizes overhead storage space. This spool carousel is an extremely flexible wire storage solution featuring a fully adjustable interior to accommodate changing inventory. The Wire Carousel is a great solution for warehouse automation programs that improves both productivity and safety.

Quick Changeover Solutions

Our patented Hollow Core Carousel is the ideal solution for storing, organizing, and accessing printing cylinders. Designed specifically for the needs of the printing and converting industry, this vertical carousel is built to effectively integrate within a busy printing production environment. The Hollow Core Carousel features a cantilevered design that reduces tooling changeover time allowing printing sleeves to slide in and out of the carousel quickly and efficiently.

Small Parts Storage

The Pan Carousel is an automated vertical carousel that provides a high overall storage volume while occupying a very small footprint resulting in a multi-benefit solution for your storage requirements. The Pan Carousel is a value-added solution for warehouse automation programs that improves both productivity and safety.

Textile & Fabric Processing

The Textile Carousel is an automated vertical carousel that stores and retrieves rolled goods efficiently and ergonomically. The motorized textile carousel is designed to effectively accommodate a wide variety of fabric rolls including woven, non-woven, knitted, synthetic, netting, and technical fabrics in a broad range of widths, diameters, and sizes. This automated storage system utilizes the vertical space in retail stores, manufacturing operations, or warehouses and brings the desired roll to the operators level, eliminating the need to manually handle textile rolls. The Textile Carousel is a value-added solution for warehouse automation programs and improves both productivity and safety.

Vertical Lift Module

The Vertical Lift Module (or VLM) is a revolutionary automated storage and retrieval system that provides smart, adaptable inventory management to maximize density and further increase productivity. Making use of 2 tray towers, one in front and one in back, along with a center elevator, trays are extracted and presented quickly, efficiently, and at an ergonomic height for the operator. Storing the trays in vertical towers allows for a minimal footprint, saving floor space up to 85%, and keeping your employees safe.

The VLM is useful in many applications, including MRO (maintenance, repair, and operating supply) for upkeep supplies, automotive repair parts, manufacturing supplies and parts, and Label Management – Pharmaceutical, OTC, Nutraceutical industries for managing their packaging labels.

Automatic Height Detection

The VLM makes use of cutting-edge technology and intelligent software to accurately measure the amount of storage space required by each tray and then performs complex calculations to determine the most efficient storage location to optimize inventory density every time items are stored or retrieved.

Bulk Storage

The Shelving Carousel is a highly flexible semi/fully automated vertical carousel designed to provide high storage density for bulky and heavier items. This automated storage system works by delivering the product directly to the operator, eliminating climbing and bending to retrieve heavy and bulky items. The carrier in this mechanical shelving concept is frequently customized for unique applications that do not conform to conventional systems. The Shelving Carousel is a value-added solution for warehouse automation programs, and improves both productivity and safety.

Increases Available Veritcal Storage: in Manufacturing Environment

The Shelving Carousel can increase your available storage capacity by utilizing the vertical space normally unoccupied by static shelving systems. With a variety of large carrier sizes the Shelving Carousel can haul up bulkier items which cannot normally be stored in a typical vertical carousel. This line of Shelving Carousels can receive a heavy duty upgrade, which provides lifting capacities of up to 34,000 lbs.

Contact us today if you are interested in a vertical carousel in your manufacturing company.