-

- Home

- Accessories

- Products

- Industries Served

- Architecture and Design

- About Us

- Blog

- Contact WooCommerce not Found

Call Us: (123) 456-7890

The Carousel is a motorized vertical carousel designed for high density storage and retrieval of items. The storage system will maximize

overhead space to save up to 80% of your floor space with every item accessible at the touch of a button. The Carousel delivers the items directly

to the operator at an ergonomic height reducing chances of injuries from lifting, bending, and pulling at sub-optimal positions.

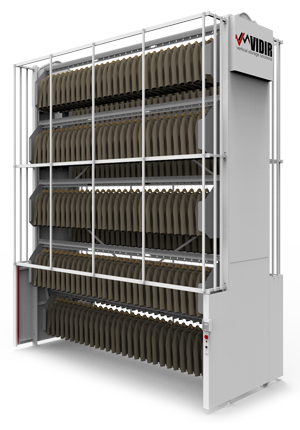

The Wire Carousel is a motorized wire storage system designed to store, retrieve, and dispense various ranges of wire, cable, rope, chain, hose (hydraulic, air, water, transfer, etc), and other materials stored in reels or spools vertically which effectively utilizes overhead storage space. This spool carousel is an extremely flexible wire storage solution featuring a fully adjustable interior to accommodate changing inventory. The Wire Carousel is a value-added solution for warehouse automation programs that improves both productivity and safety.

Increases Available Storage:

The motorized Wire Carousel increases an organizations effective storage capacity by integrating overhead space into the room’s useable storage space. This is accomplished by automating storage which turns hard to reach storage locations into easily accessible locations allowing inventory to move in and out without difficulty. Vidir’s carousel features carriers with interchangeable positions to allow for full space utilization in applications that feature high product turnover.

Increase Efficiency

The Wire Storage System features an assortment of cut/measure/re-roll attachments that may be placed in front of the wire carousel or attached to the face of the carousel to facilitate processing directly from the spool carousel itself eliminating material handling requirements found in more conventional wire storage racks.

Increase Health and Safety

The mechanical nature of this wire storage system enables spooled product near the ceiling to be retrieved at ground level by the push of a button eliminating the need for ladders, cherry pickers, and other hazardous retrieval methods. Additionally, by presenting product at an ergonomically acceptable height, the Wire Carousel reduces unnecessary bending, walking, lifting, and pushing which helps avoid workplace injuries.

Hospital Bedlift

The Bedlift is a cost effective hospital bed storage system designed to store hospital beds off of the floor and stack them securely in a vertical arrangement, which not only saves valuable floor space but removes potential fire hazards from hospital corridors.

This hospital bed storage rack will increase the hospitals maintenance departments’ capacity, organization, and product flow reducing down time, which increases the number of beds available for patient use at any given moment. Additionally, by removing unused ‘hallway beds’ from the corridors, hospitals will meet JCAHO standards for the storage of hospital beds and not risk further fines or worst case, the loss of accreditation.

Operation

The bed stacking concept is based on LIFO (Last In First Out) picking. The first bed is positioned onto the lift and raised opening up space underneath the bed for the next unit. The entire operation can easily be accomplished by a single individual simply by pushing a button.

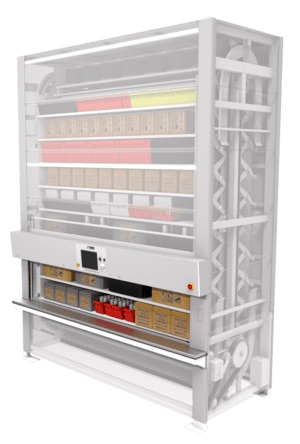

The Pan Carousel is an automated vertical carousel that provides a high overall storage volume while occupying a very small footprint resulting in a multi-benefit solution for your storage requirements. The Pan Carousel is a value-added solution for warehouse automation programs that improves both productivity and safety.

Increase Available Storage

The Pan Carousel can increase your available storage capacity by up to 70% by increasing storage density and utilizing previously inaccessible vertical space. The increased density is accomplished through a series of interchangeable dividers and removable intermediary shelves that allow you to easily reconfigure the carousel interior to a diverse range of SKU’s. Additionally, all vertical carousels operate under the product to person principle which ensures that the operators no longer concern themselves with search and retrieval functions but allow the vertical carousel to retrieve items regardless of their location.

Fast and Effective Retrieval Times

Automated vertical carousels such as the Pan Carousel, or paternoster machine in Europe, increase the effectiveness of order processing through a combination of quick retrieval times and increased picking accuracy. The Pan Carousel can be integrated with order processing software that will not only track your inventory but process pick lists which provides fast, reliable, and worry free retrieval.

Increase Safety and Health

Implementation of the product to person principle eliminates wasteful and harmful steps for stocking and retrieving parts. The Pan Carousel ensures that operators are working at ergonomically acceptable heights. This reduction in unnecessary bending, walking, and other hazardous retrieval techniques such as use of ladders and cherry pickers increases workplace safety and health.

The Garment Carousel is a motorized vertical carousel designed for high density storage and highly efficient retrieval for garments. The motorized clothing carousel is designed to effectively accommodate a wide variety of garment such as suits, coats, shirts, trousers, and gowns. This automated storage system utilizes the vertical space in retail stores, warehouses, and distribution centers to maximize the cubic footprint while simplifying inventory management, and is a value-added solution for warehouse automation programs that provides both productivity and safety.

Increases Available Storage

The Garment Carousel maximizes storage density by effectively utilizing overhead space for garment storage. This is accomplished by applying proven vertical carousel technology to achieve unparalleled garment storage within the allotted footprint.

Increase Efficiency

The Garment Carousel can be equipped with our inventory control solutions which greatly reduce retrieval times and picking accuracy. The system consists of our inventory software solution, a sophisticated touch screen controller, bar code scanning, and a pic-to-zone system. This carousel add on is ideal for large warehouses and can greatly help with order picking and fulfillment, product identification, reporting, real time inventory counts, and multi-carousel support.

Increase Health and Safety

This clothing carousel eliminates wasteful and harmful steps for stocking and retrieving clothes. The Garment Carousel ensures that operators are working at ergonomically acceptable heights and reduce unnecessary bending, walking, lifting and pushing which helps avoiding work related injuries.

The Shelving Carousel is a highly flexible semi/fully automated vertical carousel designed to provide high storage density for bulky and heavier items. This automated storage system works by delivering the product directly to the operator, eliminating climbing and bending to retrieve heavy and bulky items. The carrier in this mechanical shelving concept is frequently customized for unique applications that do not conform to conventional systems. The Shelving Carousel is a value-added solution for warehouse automation programs, and improves both productivity and safety.

Increases Available Storage:

The Shelving Carousel can increase your available storage capacity by utilising the vertical space normally unoccupied by static shelving systems. With a variety of large carrier sizes the Shelving Carousel can haul up bulkier items which cannot normally be stored in a typical vertical carousel. Moreover Vidir’s line of Shelving Carousels can receive a heavy duty upgrade which provides lifting capacities of up to 34,000 lbs. | 15,422 kg.

Fast and Effective Retrieval Times

Automated vertical carousels such as the Shelving Carousel increase the effectiveness of order processing through a combination of quick retrieval times and increased picking accuracy. The Shelving Carousel can be integrated with order processing software that will not only track your inventory but process pick lists which provides fast, reliable, and worry free retrieval.

Increase Health and Safety

Implementation of the product to person principle eliminates wasteful and harmful steps for stocking and retrieving parts. The Shelving Carousel ensures that operators are working at ergonomically acceptable heights, this reduction in unnecessary bending, walking, and other haphazard retrieval techniques such as ladders and cherry pickers increase workplace health and safety.